|  | Topic : How they adjust Belt Tension, and Wheel Alignment at Triumph Factory |  |

| | | lioneloxford | | Set |  |  | | Reg. Date | : | 01/04/2011 | | Posts | : | 231 | | Location | : | Oxfordshire, United Kingdom |

|

| | Posted : 25 Jun 2011 - 10:54 Post title : How they adjust Belt Tension, and Wheel Alignment at Triumph Factory | | | This is interesting.

The wheel spindle measurement, measured to spindle position of 0.01mm.

Now you know how accurate the factory set the belt alignment.

Link

Triumph Thunderbird

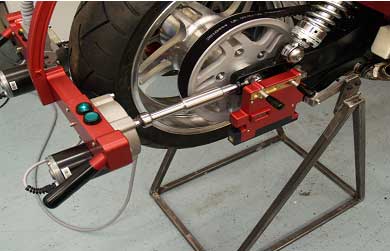

The new Triumph Thunderbird is a large 'Cruiser' type motorcycle. Part of the exceptional smoothness is derived from using a belt drive which replaces the conventional chain. It is essential that the belt is tensioned correctly. Triumph came to CLAVIS for equipment to both tension the belt automatically and to align the wheel spindle perfectly during the same operation. This was achieved by having a 4 part system. A measurement unit with an optical sensor measures the belt tension. Two units located in either side of the wheel spindle, measure wheel spindle position to 0.01mm! All three of these units are battery powered and communicate with the control cabinet by a UHF telemetry link. The fourth unit is the motor drive system which rotate the wheel spindle adjustment nuts. Bar code scanning of the bike VIN number, data logging and the printing of the operation pass certificate ticket are other features of the system.

Link

My belt is getting a little loose, been searching for a setting tool and found the above links.

Edit:

It looks like Mat1600 was right about using the machined location lugs at the end of the spindle slot for taking the measurements.

If you blow up the photos on the main website, it does look as if this position is used to locate the fixtures into place.

| | Post edited by lioneloxford on 25 Jun 2011 - 11:27 |

|

| | | davetac1 | | Thunderbird |  | | Reg. Date | : | 06/09/2010 | | Posts | : | 8,379 | | Location | : | Haverhill, Ma., United States |

|

| | Posted : 25 Jun 2011 - 13:25 Post title : Re: How they adjust Belt Tension, and Wheel Alignment at Triumph Factory (Re: lioneloxford) | | | Assuming the swing arm and motor are correctly aligned from the factory,which I doubt,lol,this unit would probably be the way to go.However,how many of these alignment units have ya ever seen at a dealership,any dealership.And if ya asked about these alignment units,I doubt any of the dealerships have even heard of em.Plus,I'll just bet that these units are Cheap,cheap,cheap to buy.lol RIGHT!!

Anyways,I believe that after reseating my swing arm and adding that extra nut on the left side to prevent the wheel from chaulking on that side,I have cracked the belt alignment code as my belt is wearing pretty much dead center now when driving in a straight line.Infact,ya might even say that dummy me "FINALLY" did somethin right for a change.lol I am learning! did somethin right for a change.lol I am learning!  Dave!!! Dave!!!

| | Post edited by davetac1 on 25 Jun 2011 - 13:26 |

|

| | | DizzE | | Thor |  |  | | Reg. Date | : | 12/07/2010 | | Posts | : | 3,141 | | Location | : | Sunnyvale, CA, United States |

|

| | Posted : 25 Jun 2011 - 14:46 Post title : Re: How they adjust Belt Tension, and Wheel Alignment at Triumph Factory (Re: davetac1) | | | Dave!!!, if someone thinks you are dummy, tell them that we don't and get over it.

It funny, being a techno-nerd, you'd think I'd ebrace all this wizz-bang, but I see how it's getting

over the top. I turned off all the extra maps in the ECU and the O2 sensors.

They wouldn't need this machine if they didn't need to align the engine to the axle with this new

framing system before they torque up the frame. That's in the SM.

IMO, this initial tension is only to do with that. And the running tension has to do with creatng

early service work. Did they design the bearings to fail early under this tension? We'll never know.

Could they? Of course! The science of controlled obsolecence is also aided by vast

compute resources.

In the future, the Nerds will ru;le the world. Then their robots will kill them (for their own good)

and rule us.

|

|

| | | davetac1 | | Thunderbird |  | | Reg. Date | : | 06/09/2010 | | Posts | : | 8,379 | | Location | : | Haverhill, Ma., United States |

|

| | Posted : 25 Jun 2011 - 15:52 Post title : Re: How they adjust Belt Tension, and Wheel Alignment at Triumph Factory (Re: DizzE) | | | I agree with ya Dizz."IF",which is the longest word in the English language,lol,the factory followed their own engine/swing arm alignment procedure like they're supposed to,which is also listed in the SM,I don't believe that any of this fancy equipment would really be neccessary and we'd all be a lot happier.However,I did buy Triumph's swing arm alignment tool for when I change the belt.But until I do that,I won't really know just how far off my swing arm is or was.But since my belt is workin just fine since my last go around with it,including reseating the swing arm,I'd have to say that's it's gotta be pretty close. Whadaya think?? Dave!!!

|

|

| | | DizzE | | Thor |  |  | | Reg. Date | : | 12/07/2010 | | Posts | : | 3,141 | | Location | : | Sunnyvale, CA, United States |

|

| | Posted : 25 Jun 2011 - 18:17 Post title : Re: How they adjust Belt Tension, and Wheel Alignment at Triumph Factory (Re: davetac1) | |

| | | Lantesh | | Set |  | | Reg. Date | : | 25/05/2011 | | Posts | : | 243 | | Location | : | United States |

|

| | Posted : 26 Jun 2011 - 16:02 Post title : Re: How they adjust Belt Tension, and Wheel Alignment at Triumph Factory | | | That machine was shown in action on the Triumph factory episode of Speedmakers. It was interesting watching how fast, and accurately it did the job. Of course once you put a few miles on the bike the belt tension and alignment will need to be checked and adjusted again. As the belt starts to break in, and I'm guessing other rubber parts in the suspension settle in as well the alignment and tension can change. Mine started squealing at about 500 or 600 miles, and I had to take it in to the dealer. I now have just over 1500 miles, and it has been fine since.

|

|

|

| |

| |

|