|

| DizzE | | Thor |  |  | | Reg. Date | : | 12/07/2010 | | Posts | : | 3,141 | | Location | : | Sunnyvale, CA, United States |

|

| | Posted : 30 Oct 2010 - 01:04 Post title : Cylinder head and combusition chamber | | | I'm hoping some folks took pictures. I'm especially interested in the ports. Also, any pictures

of the chamber side on the head? And, are the piston's flat or some shape?

EMWTK  For Science. For Science.

|

|

|

|

| FTL40 | | Jupiter |  |  | | Reg. Date | : | 13/10/2009 | | Posts | : | 1,122 | | Location | : | massachusetts, United States |

|

| | Posted : 30 Oct 2010 - 12:58 Post title : Re: Cylinder head and combusition chamber (Re: DizzE) | | | heres a picture of the bb piston, i never took a pic of the head when it was apart

Link

| 2010 tbird 1700 silver (fastest color) BC exhaust, BC airbox removal

|

|

|

|

| DizzE | | Thor |  |  | | Reg. Date | : | 12/07/2010 | | Posts | : | 3,141 | | Location | : | Sunnyvale, CA, United States |

|

| | Posted : 30 Oct 2010 - 13:55 Post title : Re: Cylinder head and combusition chamber (Re: FTL40) | | | wow...those are pancakes, for sure. Flat topped, low mass. Thanks much.

BTW, that's your 1600 piston next to it? Is that normal? I expected the color,

but those dark spots?

|

|

|

|

| FTL40 | | Jupiter |  |  | | Reg. Date | : | 13/10/2009 | | Posts | : | 1,122 | | Location | : | massachusetts, United States |

|

| | Posted : 30 Oct 2010 - 15:01 Post title : Re: Cylinder head and combusition chamber (Re: DizzE) | | | yes thats my 1600 piston with only about 100 miles on it. not sure about normal or not tho

| 2010 tbird 1700 silver (fastest color) BC exhaust, BC airbox removal

|

|

|

|

| Thatch | | Thor |  |  | | Reg. Date | : | 24/06/2009 | | Posts | : | 3,655 | | Location | : | Savannah, GA, United States |

|

| | Posted : 30 Oct 2010 - 15:52 Post title : Re: Cylinder head and combusition chamber (Re: FTL40) | | | Yeah that looks pretty close to what my cylinders looked like (though mine were darker... they had a lot more miles on them)

|

|

|

|

| DizzE | | Thor |  |  | | Reg. Date | : | 12/07/2010 | | Posts | : | 3,141 | | Location | : | Sunnyvale, CA, United States |

|

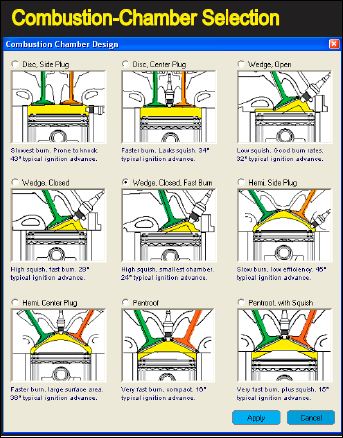

| | Posted : 31 Oct 2010 - 15:28 Post title : Re: Cylinder head and combusition chamber (Re: Thatch) | | | For modeling purposes does anyone have an idea about the shape of the compression recess in the head?

It's either #2 Flat disk. Or one of the wedge types, since the piston head is flat.

|

|

|

|

| DizzE | | Thor |  |  | | Reg. Date | : | 12/07/2010 | | Posts | : | 3,141 | | Location | : | Sunnyvale, CA, United States |

|

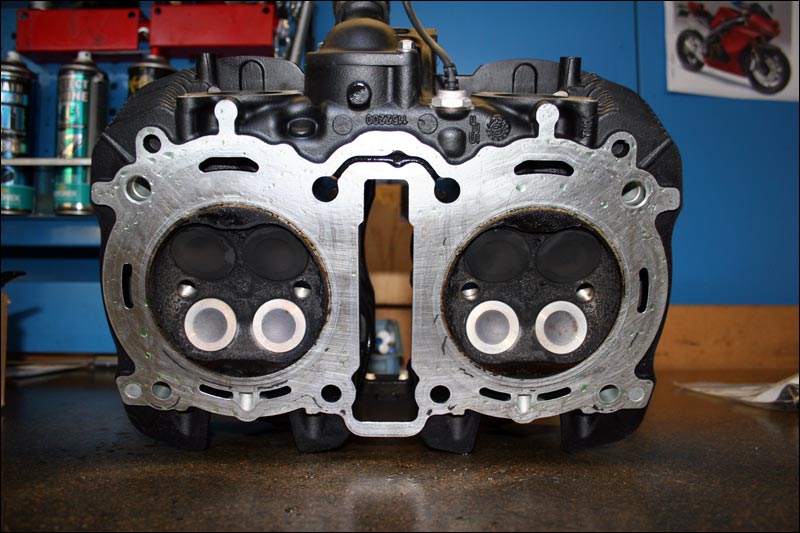

| | Posted : 06 Nov 2010 - 15:13 Post title : Re: Cylinder head and combusition chamber (Re: DizzE) | | | I knew there were some pics....from Birdy68's BB project.  Definitely a wedge, but which one? You can see from the Definitely a wedge, but which one? You can see from the

drawings it has to do with the angle of the plug to valve.

And since the piston is flush it's a closed wedge. Which one? I think from the plug angle it must be the fast burn. I used that in the Sim model. This picture verifies.

If you will notice the dark flat areas above and below the valves that keep the chamber from being a perfect circle? That, I think can be improved. It's called valve shrouding. You see the place on the intake and exit sides of the head that block the air curtain flow next to the cylinder wall and the valve? Careful work can smooth that like the sides near the spark plugs. There may be a coolant gallery there, however.

- Un-shroud the valves - better swirl, better combustion. Faster flow at beginning of valve lift. More TQ.

|

|

|

|

| DizzE | | Thor |  |  | | Reg. Date | : | 12/07/2010 | | Posts | : | 3,141 | | Location | : | Sunnyvale, CA, United States |

|

| | Posted : 06 Nov 2010 - 15:32 Post title : Re: Cylinder head and combusition chamber (Re: DizzE) | | | Ah, a great shot of the intake port and valve. Birdy!! Here we see three areas for improvement.

- grind down the valve guide to flush with the port roof.

- flow the intake bowl. That's the area that the valve stem runs through. Here you can bias the

shape of the flow toward the previously shrouded, "short side" it's called. That's the turn down to valve

we see at the bottom of pic. Or the floor of the port.

- add a venturi effect at the short side turn down on the intake side. Use Epoxy to create a flat spot in the

floor, the full width of the port. But, only 65% of the valve diameter in height.

| | Post edited by DizzE on 06 Nov 2010 - 15:32 |

|

|

|

| BaltoThunder | | Set |  |  | | Reg. Date | : | 16/10/2009 | | Posts | : | 43 | | Location | : | United States |

|

| | Posted : 06 Nov 2010 - 20:40 Post title : Re: Cylinder head and combusition chamber (Re: DizzE) | | | That setup is much closer to a hemi or pentroof design than any wedge.

| Ride, shoot straight, and speak the truth!

2nd Officer Harbor Chapter #215 Southern Cruisers Riding Club

|

|

|

|

| zolti | | Thor |  |  | | Reg. Date | : | 23/03/2010 | | Posts | : | 3,127 | | Location | : | newcastle , United Kingdom |

|

| | Posted : 06 Nov 2010 - 21:09 Post title : Re: Cylinder head and combusition chamber (Re: BaltoThunder) | | |

BaltoThunder wrote:

That setup is much closer to a hemi or pentroof design than any wedge. |

|

+1!!

|

|

|

|

| DizzE | | Thor |  |  | | Reg. Date | : | 12/07/2010 | | Posts | : | 3,141 | | Location | : | Sunnyvale, CA, United States |

|

| | Posted : 06 Nov 2010 - 21:54 Post title : Re: Cylinder head and combusition chamber (Re: zolti) | | | True...I'm not that good a 3-d visualizer. I see what you mean. So, a flat piston in a two plug penta. That seems like

a pretty big combustion chamber. Valves don't open far. 7 - 8 mm. If I model with a penta it's about the same.

We can see from the Maps in the ECU about what the base ignition is...maybe 15 degrees. Works for me.

|

|

|

|

| mag10 | | Set |  |  | | Reg. Date | : | 05/02/2010 | | Posts | : | 485 | | Location | : | Wisconsin, United States |

|

| | Posted : 08 Nov 2010 - 12:16 Post title : Re: Cylinder head and combusition chamber (Re: DizzE) | | | I agree with unshrouding the valve to improve the chamber, and a real good polish job to get rdid of the casting surface in the chamber. This head looks very similar (as far as the combustion chamber layout goes) to the smaller twins, which is good because we already know what potential is there.

the only down side I see to opening up the heads a bit is that deshrouding with lower the compression a bit and there are no other piston option available (that I know of) Shaving the head a bit is likely to cause some challenges with the cam chain and timing.

|

|

|

|

| DizzE | | Thor |  |  | | Reg. Date | : | 12/07/2010 | | Posts | : | 3,141 | | Location | : | Sunnyvale, CA, United States |

|

| | Posted : 08 Nov 2010 - 14:56 Post title : Re: Cylinder head and combusition chamber (Re: mag10) | | | Inside the software is a combustion chamber sub-model. I am always very surprised at how much the head gasket plays a role.

Two items in particular can be adjusted for the gasket. If I calculate everything based on what I know, I can derive the geometry.

I know what the final compressed vol is, for example, based on bore/stroke and 9.7 compression. This gives a max thick gasket.

0.15 inch crushed. So, use a thinner gasket.

Also, gasket bore is oversized. 4.217 bore. I used 4.250 for gasket bore. That few hundredths makes a big difference.

Also, advancing the cam adds actual dynamic compression. Also, torque seems less sensitive to compression changes than HP.

(still studying that)

It's funny, I was brought up on terms like bore and stroke, 4 barrel hemi, port and polish. I never really knew what all that meant.

But cool to say when you are 14 years old. Times have changed with computers.

Port and shot peen, is what they do now. No polish. Bead blast. Now that full CFD can be simulated, you can see that

polish works against swirl.

Now they may have shrouded the short sides on purpose, to get the air curtain confined to the middle, in/out, but less swirl.

And there may be something else cast in. But, it's a casting and there is only so much you can do. Un-shrouding is laborious

hand work. Error prone. Not a mass product technique. Also, perhaps they defeat some reversion and waste, this way.

For TQ, I want more swirl. I want the charge in faster and exhaust out faster. So, un-shroud for

Empty-Fill speed, and more swirl, if possible. Make up the slight difference elsewhere.

|

|

|